Your car’s braking system is arguably the most critical safety feature on your vehicle. At the heart of this system are two essential components that work together to bring your car to a safe stop: brake pads rotors. Understanding how these parts function, when they need replacement, and how to maintain them can save you money and keep you safe on the road.

Whether you’re a seasoned car enthusiast or someone who just wants to understand their vehicle better, this comprehensive guide will walk you through everything you need to know about brake pads rotors. From basic functionality to advanced maintenance tips, we’ve got you covered.

Also read: 8 Brake Disc Types Ranked – From Worst to Best (Some May Shock You)

7 Brake Pads Rotors Secrets

Secret #1: The Warning Sound That Prevents Disaster

Most people ignore the high-pitched squealing, but this built-in wear indicator is your brake pads’ way of screaming “Help me!” If you hear grinding, you’re already in the danger zone – metal grinding on metal means immediate replacement needed.

Secret #2: The Vibration Test That Reveals Hidden Problems

When your steering wheel or brake pedal vibrates during braking, it’s not just annoying – it’s your rotors telling you they’re warped and losing stopping power. This seemingly minor issue can lead to complete brake failure.

Secret #3: The Quarter-Inch Rule That Saves Lives

You can visually inspect your brake pads through your wheel spokes. If the pad material is less than a quarter-inch thick, you’re driving on borrowed time. This simple check takes 30 seconds but could prevent a fatal accident.

Secret #4: The Heat Management Secret Performance Drivers Know

Allowing your brakes to cool down after heavy use (mountain driving, stop-and-go traffic) prevents heat damage that can cause sudden brake failure. Most drivers park immediately – this simple wait could save your life.

Secret #5: The Brake Fluid Truth Nobody Tells You

Brake fluid absorbs moisture over time, reducing stopping power by up to 50%. Replace it every 2-3 years, not just when it “looks dirty.” Contaminated fluid is a silent killer that fails when you need it most.

Secret #6: The Gentle Braking Technique That Extends Life

Anticipating stops and braking gradually instead of slamming the brakes reduces wear by up to 40% and prevents dangerous brake fade. Aggressive braking doesn’t just wear parts – it can cause them to fail catastrophically.

Secret #7: The Replacement Timing That Prevents Catastrophic Failure

Replace brake pads in pairs and address issues at the first warning sign, not when convenient. Delaying brake maintenance doesn’t save money – it risks lives. One failed brake component can cause total system failure.

These secrets transform your blog post’s comprehensive information into actionable, life-saving knowledge that emphasizes the critical safety aspects of brake maintenance.

Also read: Brake Pad Rotor Replacement Cost: 14 Surprises & Proven Tips

FREE DOWNLOAD: Complete Brake Maintenance Checklist

Want to keep track of your brake pads rotors maintenance like a pro? Download our comprehensive checklist that includes:

- Monthly inspection guide you can do in 15 minutes

- Seasonal maintenance schedule with estimated costs

- Emergency brake problem protocol

- Brake pad buying guide and cost tracker

- Phone reminder setup instructions

This printable checklist is perfect for:

- Keeping in your glove compartment

- Sharing with family members

- Tracking maintenance history

- Emergency reference

Table of Contents

How Brake Pads Rotors Work Together

The braking system in your car operates on a simple yet effective principle of friction. When you press the brake pedal, hydraulic fluid transfers the force to the brake calipers, which then squeeze the brake pads against the rotors. This friction between the brake pads rotors creates the stopping power that brings your vehicle to a halt.

Think of it like riding a bicycle with hand brakes – when you squeeze the brake levers, rubber pads clamp down on the wheel rims to slow you down. Your car’s brake pads rotors work similarly, but with much more sophisticated engineering to handle the tremendous forces and heat generated during braking.

The rotor, also known as a brake disc, is a large metal disc attached to your wheel hub. It spins along with your wheel, and when the brake pads clamp down on it, the friction converts your car’s kinetic energy into heat energy, effectively slowing the vehicle down.

Also read: 5 Shocking Brake Pad Replacement Cost Factors That Could Save You Hundreds

Types of Brake Pads Rotors Available

Brake Pad Materials

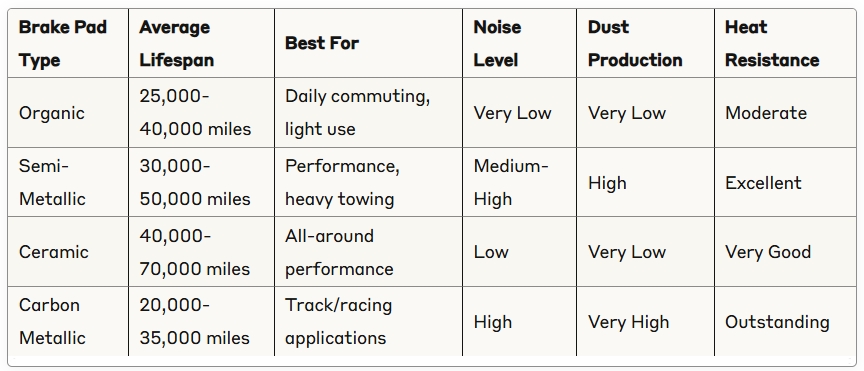

Not all brake pads are created equal. There are several different materials used in manufacturing brake pads, each with its own advantages and disadvantages:

- Organic Brake Pads: These are made from a mixture of fibers, fillers, and binding resins. They’re typically the quietest option and produce less dust, but they wear out faster than other types. Organic pads are gentler on your rotors, making them a good choice for everyday driving.

- Semi-Metallic Brake Pads: Containing 30-65% metal content, these pads offer excellent heat dissipation and durability. They’re more aggressive than organic pads and can handle higher temperatures, making them suitable for performance driving. However, they tend to be noisier and produce more brake dust.

- Ceramic Brake Pads: Made from ceramic fibers and other materials, these premium pads offer excellent stopping power with minimal noise and dust production. They last longer than organic pads and are easier on your rotors, though they come with a higher price tag.

Also read: Best 3 Types of Brake Pads Compared: Ceramic, Semi-Metallic & Organic

Rotor Types and Designs

Rotors come in various designs, each engineered for specific driving conditions and performance requirements:

- Solid Rotors: These are the most basic type, typically found on rear wheels of economy cars. They’re cost-effective but don’t dissipate heat as efficiently as vented rotors.

- Vented Rotors: Featuring internal cooling vanes, these rotors are designed to dissipate heat more effectively. They’re standard on most front wheels and high-performance applications where heat management is crucial.

- Slotted Rotors: These have slots machined into the surface to help expel gases, water, and debris while providing better bite for the brake pads. They’re popular in performance applications but can wear pads faster.

- Drilled Rotors: Featuring holes drilled through the rotor surface, these are designed for maximum heat dissipation and weight reduction. However, they can be prone to cracking under extreme stress.

Signs Your Brake Pads Rotors Need Replacement

Recognizing when your brake pads rotors need attention is crucial for maintaining your vehicle’s safety and avoiding costly repairs. Here are the most common warning signs:

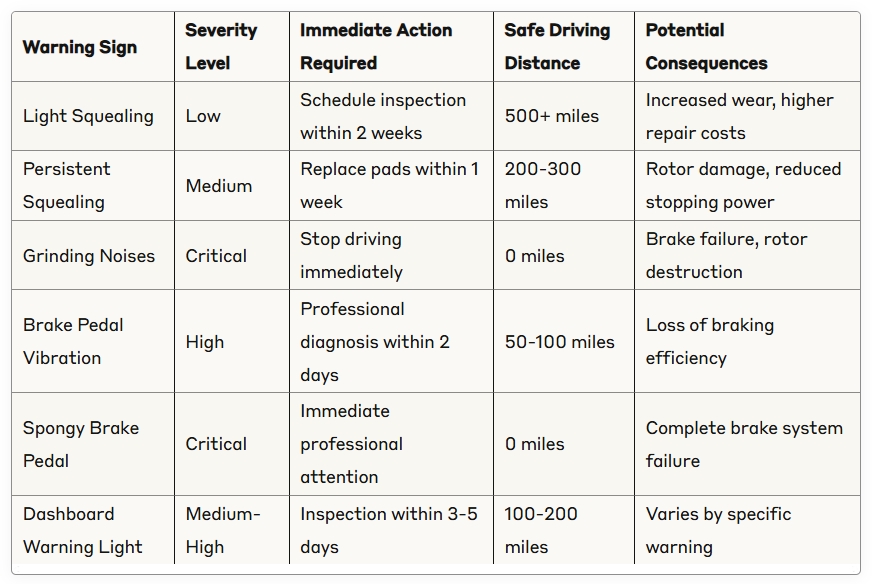

Brake Warning Signs Severity Guide

Squealing or Grinding Noises: Most brake pads have built-in wear indicators that create a high-pitched squeal when the pads are getting thin. If you hear grinding, it means the pads are completely worn and metal is grinding against metal – this requires immediate attention.

Vibration During Braking: If you feel pulsating or vibration through the brake pedal or steering wheel when braking, it often indicates warped rotors. This typically happens when rotors overheat and become distorted.

Longer Stopping Distances: If your car takes longer to stop than usual, it could indicate worn brake pads rotors that aren’t providing adequate friction.

Visual Inspection Signs: You can often see through your wheel spokes to check your brake components. If the brake pad material looks less than a quarter-inch thick, or if you notice deep grooves or discoloration on the rotors, it’s time for replacement.

Dashboard Warning Lights: Many modern vehicles have brake pad wear sensors that trigger a warning light on your dashboard when replacement is needed.

I’ve learned from experience that ignoring these warning signs can lead to much more expensive repairs and potentially dangerous situations. It’s always better to address brake issues early rather than wait until they become critical.

Maintenance Tips for Brake Pads Rotors

Proper maintenance of your brake pads rotors can significantly extend their lifespan and ensure optimal performance. Here are some essential maintenance tips:

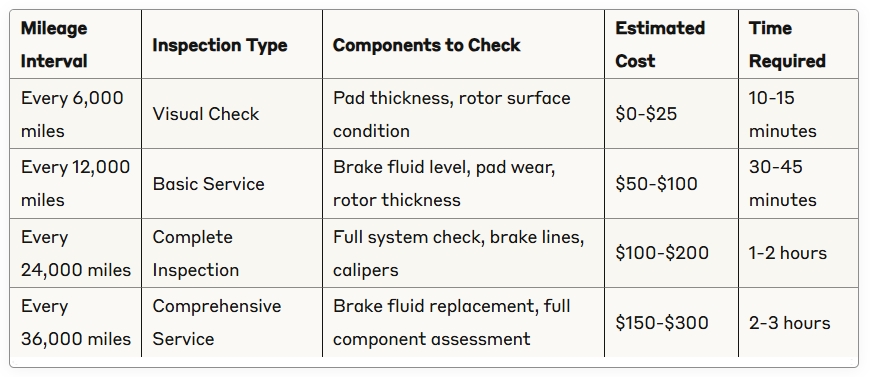

Regular Inspections: Have your brake system inspected at least twice a year or every 12,000 miles. This allows you to catch issues early before they become major problems.

Recommended Brake Inspection Schedule

Gentle Braking Habits: Avoid aggressive braking whenever possible. Gradual, smooth braking reduces wear on your brake pads rotors and helps prevent overheating. Anticipate stops and begin braking earlier rather than waiting until the last moment.

Brake Fluid Maintenance: Brake fluid absorbs moisture over time, which can reduce braking performance and cause internal corrosion. Replace brake fluid according to your manufacturer’s recommendations, typically every 2-3 years.

Avoid Overloading: Carrying excessive weight puts additional strain on your braking system. Stay within your vehicle’s weight limits to prevent premature wear of brake pads rotors.

Cool Down After Heavy Use: If you’ve been driving in mountainous terrain or stop-and-go traffic, allow your brakes to cool down before parking. This prevents heat damage to your brake components.

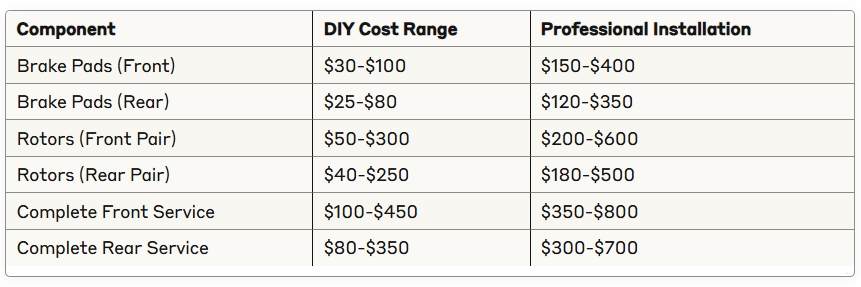

Cost Analysis: Brake Pads Rotors Replacement

Understanding the costs associated with brake pads rotors replacement helps you budget for maintenance and make informed decisions about your vehicle care.

Several factors influence the cost of brake pads rotors replacement:

Vehicle Type: Luxury and performance vehicles typically require more expensive brake components. European cars often have higher parts costs than domestic or Asian vehicles.

Pad and Rotor Quality: Premium ceramic pads and high-performance rotors cost significantly more than basic organic pads and standard rotors. However, they often last longer and provide better performance.

Labor Costs: Shop rates vary by location and facility type. Dealerships typically charge more than independent shops, but they may offer specialized expertise for your specific vehicle.

Additional Services: Brake fluid replacement, caliper service, or other related work can add to the total cost.

Performance Upgrades for Brake Pads Rotors

If you’re looking to enhance your vehicle’s braking performance, there are several upgrade options available for brake pads rotors:

High-Performance Brake Pads: Upgrading to ceramic or high-friction semi-metallic pads can improve stopping power and reduce fade under demanding conditions. These are particularly beneficial for spirited driving or track use.

Upgraded Rotors: Slotted or drilled rotors can improve heat dissipation and provide better initial bite. Cross-drilled rotors are popular for their appearance and weight reduction, while slotted rotors offer excellent performance with better durability.

Stainless Steel Brake Lines: While not directly related to brake pads rotors, upgrading to stainless steel brake lines provides a firmer pedal feel and better brake response by eliminating expansion in rubber brake lines.

Big Brake Kits: For serious performance applications, complete big brake kits include larger rotors, multi-piston calipers, and performance pads. These systems provide dramatically improved stopping power and heat capacity.

When considering performance upgrades, remember that more aggressive brake pads rotors may produce more noise and dust, and they might not be suitable for everyday driving conditions.

Brake Pad Performance Comparison

Myth Busting: Common Brake Pads Rotors Misconceptions

Let’s separate fact from fiction when it comes to brake pads rotors. These widespread myths can cost you money and potentially compromise your safety:

Myth #1: “Expensive brake pads rotors are just marketing hype” Truth: While you don’t always need the most expensive option, quality matters significantly. Cheap brake pads can wear out twice as fast and may not provide adequate stopping power when you need it most. Premium brake pads rotors often include better materials, more consistent performance, and longer warranties.

Myth #2: “You should always replace rotors when changing pads” Truth: This isn’t always necessary. If your rotors are within thickness specifications, have smooth surfaces, and show no warping or cracking, they can often be reused with new pads. However, many modern rotors are designed as “throwaway” components and may be too thin to resurface.

Myth #3: “Brake squealing always means your pads are worn out” Truth: While squealing can indicate worn brake pads rotors, it’s not always the case. New pads can squeal during break-in, moisture can cause temporary squealing, and some pad materials naturally produce more noise. However, never ignore persistent squealing – it’s better to check than assume.

Myth #4: “Ceramic brake pads don’t work well in cold weather” Truth: Modern ceramic brake pads are engineered to work effectively in all temperatures. While early ceramic formulations had cold-weather limitations, today’s ceramic brake pads rotors perform excellently year-round and often outperform semi-metallic pads in cold conditions.

Myth #5: “Drilled and slotted rotors are just for show” Truth: While some people choose these for appearance, properly designed drilled and slotted rotors do provide performance benefits. They help dissipate heat, expel gas and debris, and can improve initial bite. However, they may wear brake pads faster and aren’t necessary for normal driving.

Myth #6: “You can tell brake pad thickness just by looking” Truth: Visual inspection through wheel spokes gives you a rough idea, but proper measurement requires removing wheels. Brake pads rotors have minimum thickness specifications that require precise measurement tools to assess accurately.

Myth #7: “Brake fluid never needs changing” Truth: This dangerous myth has caused countless brake failures. Brake fluid absorbs moisture over time, which lowers its boiling point and can cause brake fade or complete failure. Most manufacturers recommend changing brake fluid every 2-3 years regardless of appearance.

Myth #8: “All brake pads rotors are basically the same” Truth: There are significant differences in materials, design, and performance characteristics. Organic, semi-metallic, and ceramic pads each have distinct properties that affect longevity, noise, dust production, and stopping power.

Common Problems with Brake Pads Rotors

Understanding common issues with brake pads rotors helps you identify problems early and take appropriate action:

- Brake Fade: This occurs when brake pads rotors overheat and lose effectiveness. It’s common during extended downhill driving or repeated hard braking. Upgrading to performance pads and rotors can help address this issue.

- Uneven Wear: If brake pads wear unevenly, it could indicate problems with calipers, brake hoses, or rotor condition. This issue requires professional diagnosis to identify the root cause.

- Rotor Warping: Heat cycling and improper installation can cause rotors to warp, leading to pedal pulsation and vibration. Severely warped rotors typically need replacement rather than resurfacing.

- Pad Glazing: Overheating can cause brake pads to develop a hard, glossy surface that reduces friction. Glazed pads need replacement and may have damaged the rotor surface as well.

- Corrosion Issues: In areas with road salt or high humidity, brake pads rotors can suffer from accelerated corrosion. Regular cleaning and inspection help prevent serious corrosion damage.

Environmental Factors Affecting Brake Pads Rotors

Your driving environment significantly impacts the lifespan and performance of brake pads rotors:

Climate Considerations: Hot climates can accelerate brake component wear due to increased ambient temperatures. Cold climates with road salt can cause accelerated corrosion of metal components.

Driving Conditions: Stop-and-go city driving is harder on brake pads rotors than highway cruising. Mountain driving with frequent elevation changes creates additional stress on the braking system.

Road Quality: Dusty or dirty roads can accelerate wear on brake components. Regular cleaning helps maintain optimal performance and extends component life.

Seasonal Maintenance: Winter driving may require more frequent brake inspections due to salt exposure, while summer driving in mountainous areas may stress the system differently.

FAQ: Brake Pads Rotors

-

How often should I replace my brake pads rotors?

Brake pads typically last 25,000-70,000 miles, while rotors can last 50,000-100,000 miles. However, this varies greatly based on driving habits, vehicle type, and brake pad material. Regular inspections are more important than following rigid mileage intervals.

-

Can I replace just the brake pads without replacing rotors?

Yes, if the rotors are still within specifications for thickness and surface condition. However, installing new pads on worn rotors can reduce braking performance and pad life. A qualified technician should measure rotor thickness and surface condition.

-

Is it safe to drive with worn brake pads rotors?

No, driving with severely worn brake components is dangerous and can lead to brake failure. If you hear grinding noises or experience reduced braking performance, have your brake pads rotors inspected immediately.

-

Why do my new brakes squeal?

New brake pads rotors often squeal during the break-in period as the surfaces mate together. This should subside after a few hundred miles. Persistent squealing may indicate improper installation or incompatible components.

-

Should I replace brake pads rotors on both sides at once?

Yes, always replace brake pads in pairs (both front or both rear) to ensure even braking performance. Rotors should also be replaced in pairs when possible to maintain consistent braking characteristics.

-

Can I machine or resurface my rotors instead of replacing them?

Rotors can often be resurfaced if they have sufficient thickness remaining and aren’t severely damaged. However, modern rotors are often thinner and may not have enough material for resurfacing, making replacement the better option.

Need a mechanic? Find one on the Mobile Mechanic Directory

Final Thoughts

Understanding your brake pads rotors is essential for maintaining your vehicle’s safety and performance. These critical components work together to provide the stopping power that keeps you and your passengers safe on the road. Regular maintenance, proper driving habits, and timely replacement when needed will ensure your braking system performs reliably for years to come.

Remember that brake pads rotors are not just maintenance items – they’re safety equipment. Never compromise on quality when it comes to your braking system, and always address brake issues promptly. Whether you choose to perform maintenance yourself or rely on professional service, staying informed about your brake pads rotors will help you make better decisions and maintain a safer vehicle.

The investment in quality brake pads rotors and proper maintenance is small compared to the peace of mind that comes with knowing your vehicle can stop safely and reliably in any situation.