Introduction: Why Understanding Brake Disc Types Is More Important Than You Think

Have you ever hit your brakes hard and felt that reassuring grip as your car came to a stop? That’s your brake discs at work! As someone who’s replaced more brake discs than I care to count (both professionally and on my weekend project cars), I can tell you that brake disc types are perhaps the most overlooked yet critical safety component on your vehicle.

Did you know that your choice of brake rotor type can affect everything from your stopping distance to how much you’ll spend on maintenance over your car’s lifetime? It’s true! A study by the National Highway Traffic Safety Administration found that brake-related issues contribute to approximately 22% of vehicle mechanical failure crashes. That’s a startling statistic that highlights just how important understanding your brake disc types really is.

In my 15+ years working with vehicle braking systems, I’ve seen firsthand how the right brake disc type can transform a vehicle’s performance, while the wrong one can lead to premature wear, costly replacements, and even dangerous driving conditions. Whether you’re a weekend warrior hitting the track, a daily commuter navigating stop-and-go traffic, or someone who occasionally hauls heavy loads, your brake disc type needs are unique.

Also read: Brake Pad Rotor Replacement Cost: 14 Surprises & Proven Tips

Understanding the Basics of How Brake Disc Types Function

Before we compare the different brake rotor types available today, let’s quickly cover the fundamentals of how these crucial components actually work in your vehicle.

Brake discs (also called rotors) are metal discs attached to your wheel hubs.

- When you press the brake pedal, calipers squeeze brake pads against these discs.

- The resulting friction converts kinetic energy (motion) into thermal energy (heat).

- This process slows and stops your vehicle’s wheels from turning.

The effectiveness of this seemingly simple process depends heavily on several key factors:

- Material composition – affects heat capacity, wear resistance, and weight

- Design architecture – influences cooling efficiency and performance in various conditions

- Surface treatments – impact initial bite, noise levels, and corrosion resistance

- Manufacturing quality – determines uniformity, balance, and overall durability

I remember my first brake job on my dad’s old Ford pickup. The cast iron rotors were so heavy I could barely lift them! Modern brake rotor types have come a long way since then, with advanced materials and innovative designs dramatically improving performance while often reducing weight.

The market now offers numerous brake rotor types optimized for different driving conditions, vehicle types, and performance requirements. Whether you’re focused on daily driving, towing, or high-speed track performance, there’s a brake rotor type suited to your needs.

Also read: What are brake calipers & 5 alarming signs they are failing

1. Solid Brake Discs: The Most Basic of Brake Disc Types

When it comes to brake rotor types, solid discs represent the most traditional and straightforward design. These dependable workhorses have been around since disc brakes became standard on everyday vehicles.

- Single-piece construction with no internal vanes or channels

- Typically made from cast iron with varying carbon content

- Usually thinner and lighter than other brake rotor types

- Most commonly found on smaller, lighter vehicles

- Generally the most affordable option available

Back in my apprenticeship days, solid discs were practically the default for budget-friendly sedans and compact cars. I vividly remember servicing a fleet of delivery vehicles that ran exclusively on solid discs. Why? Because they were cheap, reliable, and got the job done for light-duty driving.

Solid Brake Disc Performance Characteristics

Solid brake discs deliver adequate stopping power for everyday driving—especially in lighter vehicles. But they’re not without their drawbacks:

- Heat builds up quickly compared to vented brake rotor types

- More susceptible to brake fade during sustained braking

- Best suited for city driving with frequent, low-speed stops

- Ideal for vehicles with modest braking requirements

Durability of Solid Brake Disc Types

Their simplicity is both a benefit and a limitation:

- Fewer parts mean fewer things that can go wrong

- Thinner design leads to faster wear

- More vulnerable to warping under high heat

- Typically last 30,000–50,000 miles with proper care

Cost Efficiency of Solid Brake Discs

If you’re shopping based on price, solid discs are tough to beat:

- Lowest upfront cost among all brake disc types

- Quickest and easiest to install (saving labor time)

- Cheapest to replace when the time comes

- Great value for light, low-performance vehicles

Over the years, I’ve installed hundreds of solid discs on commuter cars, budget builds, and even project beaters. If your driving style is mellow and your vehicle is light, these classic brake rotor types offer unbeatable bang for your buck. Just don’t expect race-day performance!

2. Vented Brake Discs: The Most Popular of Modern Brake Disc Types

If you’ve looked under the wheels of most modern vehicles, chances are you’ve seen vented discs in action. Among all brake disc types, vented discs are one of the most widely used — and for good reason. These designs mark a major leap forward in braking performance and heat management.

- Two parallel disc surfaces connected by internal vanes

- Air channels between the surfaces promote continuous airflow and cooling

- Available in straight-vane or curved-vane configurations

- Commonly found on modern passenger vehicles

- Offer superior heat dissipation compared to other brake disc types, especially solid discs

I’ll never forget the first time I upgraded my old commuter car from solid to vented discs. I used to dread my mountain drives because of severe brake fade on the downhill. After switching to vented discs, that issue disappeared overnight — it was a total game changer.

Performance Advantages of Vented Brake Disc Types

Vented discs really shine in situations where managing heat is essential:

- Up to 70% better cooling efficiency compared to solid brake rotor types

- Dramatically reduced brake fade during repeated or prolonged braking

- More consistent brake pedal feel, even under heavy loads

- Greater resistance to warping from thermal stress

- Overall more reliable braking under demanding conditions

Where Vented Brake Disc Types Are Commonly Used

You’ll find these versatile discs across a wide range of vehicles:

- Mid-size to full-size passenger cars

- SUVs and crossovers

- Light-duty trucks and commercial vehicles

- Performance-focused models

- Vehicles used for towing or carrying heavier loads

Vented Discs: A Smart Investment?

While vented discs carry a slightly higher price tag than some other brake rotor types, they often prove to be the smarter long-term choice:

- Moderate cost increase (usually 15–30% more than solid discs)

- Extended lifespan thanks to better heat management

- Lower risk of premature warping or rotor failure

- Improved safety and performance justify the extra cost

- Average lifespan ranges from 40,000 to 60,000 miles with regular use

From years of experience in the shop, I can confidently say vented discs offer the best balance of durability, performance, and cost for the average driver. Among the many brake rotor types out there, these are the reliable middle ground that suit most real-world driving conditions.

4. Drilled Brake Discs: One of the Flashiest Brake Disc Types on the Market

Now we’re stepping into the world of specialized brake disc types. Drilled brake discs are instantly recognizable thanks to their distinctive patterns of holes machined through the friction surface. Often seen on performance cars, they offer a mix of function and form that appeals to both enthusiasts and aesthetics-minded drivers.

- Holes are drilled perpendicularly through the disc surface

- Commonly paired with vented disc architecture for enhanced cooling

- Available in different hole patterns and counts depending on the vehicle and application

- Their visual appeal shines through open-spoke alloy wheels

- Widely marketed as a performance upgrade among brake rotor types

I’ll admit, I was skeptical the first time I bolted a set of drilled discs onto my weekend track car. But after a rain-soaked track session where my braking stayed consistent while others were skidding through puddles, I was sold. That wet-weather confidence made a real difference.

Performance Perks of Drilled Brake Disc Types

Drilled discs offer several theoretical and practical benefits that have earned them a solid following:

- Improved gas and moisture evacuation from the pad-to-rotor interface

- Reduced brake fade, especially in wet conditions

- Slightly reduced unsprung weight compared to solid or vented brake disc types

- Sharper initial bite during pedal application

- Sporty, performance-inspired look many drivers love

Potential Downsides of Drilled Brake Discs

Not every upgrade is a slam dunk. Drilled discs come with a few trade-offs:

- Holes introduce potential stress points that can lead to cracking over time

- Less suited for high-heat scenarios (like aggressive track use)

- Can accelerate brake pad wear due to the sharp hole edges

- May produce more brake dust and noise than non-drilled brake rotor types

- Often more expensive than similar solid or vented options

Cost Considerations for Drilled Brake Discs

The cost of these performance-focused brake disc types can vary significantly:

- Entry-level options cost about 20–40% more than standard vented discs

- Premium brands with higher-quality metallurgy may cost 50–100% more

- Shorter replacement cycles can drive up long-term costs

- High-end versions are often bundled with slotted designs for even greater performance

From a mechanic’s perspective, drilled discs make the most sense for enthusiasts who drive hard, value aesthetics, or encounter wet conditions often. But for your average daily driver? These brake disc types are more show than substance — and that’s totally fine if that’s what you’re after.

5. Slotted Brake Discs: One of the Toughest Brake Disc Types for High Performance

If you’re serious about performance driving, slotted discs are one of the brake disc types you should absolutely consider. These specialized rotors feature precision-machined grooves — or “slots” — across the friction surface that offer serious functional advantages under high-stress conditions.

- Linear or curved slots cut into the disc face

- Slot depth, angle, and spacing vary depending on the brand and intended use

- Commonly paired with vented architecture for enhanced cooling

- Designed primarily for racing, track days, and high-performance street applications

- Found increasingly on modern sports cars and performance trims

I first encountered slotted brake disc types during a professional driving course. The instructor’s vehicle maintained rock-solid braking lap after lap — no fade, no drama. After that experience, I was hooked on their consistency in high-heat situations.

What Makes Slotted Brake Disc Types Stand Out?

Slotted discs bring several specific advantages to the table for drivers who demand more:

- Enhanced gas and brake dust evacuation

- Maintains braking efficiency under repeated hard stops

- Built-in pad “wiping” action helps clean debris and moisture

- More crack-resistant than drilled brake disc types

- Ideal for high-speed or high-weight braking scenarios

Where You’ll Find Slotted Brake Disc Types

Slotted discs aren’t typically used on everyday commuters, but they shine in high-performance environments:

- Track and motorsport vehicles

- Performance-tuned street cars

- Heavy-duty towing applications

- Emergency vehicles and pursuit-rated police cars

- Any vehicle frequently subjected to brake fade

Slotted Disc Durability and Longevity

Among the premium brake disc types, slotted discs offer robust durability if used properly:

- Better resistance to cracking under extreme heat compared to drilled discs

- Can wear brake pads faster due to the aggressive wiping action

- Excellent longevity when paired with performance pads

- Often made with high-carbon or upgraded metallurgy to handle thermal stress

Cost Breakdown for Slotted Brake Discs

Slotted brake disc types come at a premium but may offer long-term savings for performance-minded drivers:

- Typically 30–60% pricier than standard vented discs

- Installation by professionals is strongly recommended

- Best performance achieved when paired with matched high-performance pads

- Ideal for drivers who consistently experience heavy braking loads

- For some, the added durability reduces long-term rotor and pad replacement costs

From my time setting up brake systems for amateur racing teams, I can confidently say slotted brake disc types offer some of the best stopping power and heat resistance you can get without going full race-spec. For the average driver? They’re impressive but probably more than you’ll ever need.

6. Composite and Two-Piece Brake Disc Types: Advanced Engineering for Performance Drivers

For those chasing top-tier braking performance without venturing into exotic carbon-ceramic territory, composite and two-piece brake disc types offer some of the most refined and effective solutions on the market today.

- Outer friction ring and inner hub (or “hat”) are separate components

- Connected using floating pins, bobbins, or specialized hardware

- Often a mix of materials — aluminum hats with cast iron or steel friction rings

- Commonly found in vented, drilled, slotted, or hybrid configurations

- Used extensively in motorsport and high-performance street cars

The first time I installed two-piece rotors on a track-prepped BMW, I was blown away by the weight difference — and so was the owner. He later told me the car felt sharper on throttle and more responsive in corners thanks to the drop in unsprung mass.

What Sets These Brake Disc Types Apart?

Among the various brake disc types, composite and two-piece designs stand out due to their intelligent construction:

- 15–25% lighter than standard one-piece rotors

- Floating design reduces risk of thermal warping

- Better heat distribution and dissipation

- Decreased stress on wheel bearings and suspension components

- Sleek, motorsport-inspired look visible through alloy wheels

Performance Enhancements You Can Feel

These premium brake disc types deliver real-world benefits in high-demand driving:

- Reduced unsprung mass for sharper handling and faster response

- Improved pedal feel and brake modulation at high speeds

- Greater resistance to fade during long track sessions or spirited drives

- Superior thermal management enhances component longevity

- Lower rotational inertia contributes to improved efficiency

Investment vs. Value: Are These Brake Disc Types Worth It?

There’s no sugarcoating it — these advanced brake disc types come with a steep price tag:

- Often 2–4x the cost of equivalent one-piece discs

- May require specialized tools or expertise for installation

- Limited aftermarket support for certain models

- Repairs typically mean full replacement, not component fixes

- Best value realized in performance or weight-sensitive builds

From my professional experience, composite and two-piece brake disc types are ideal for drivers seeking to extract every last bit of performance from their setup — whether on the street or at the track. For daily commuters, the cost usually outweighs the benefits, but if you’re after precision, control, and a bit of wow factor, they’re hard to beat.

7. Carbon Ceramic Brake Disc Types: The Pinnacle of Braking Performance

At the absolute pinnacle of brake disc types, carbon ceramic discs represent the most advanced technology currently available for production vehicles. Originally developed for aerospace and Formula 1, this exotic option has since made its way into high-performance road cars.

- Constructed from a carbon fiber-reinforced ceramic matrix

- Up to 70% lighter than traditional cast iron discs

- Handles temperatures as high as 1600°C without performance loss

- Recognizable by their matte gray or amber finish

- Requires specially formulated brake pads

I had the rare opportunity to install a set of carbon ceramic rotors during a high-performance training session. The difference in weight alone was astonishing — lifting them felt like handling a carbon fiber prop instead of a core component of a braking system. It was a true glimpse into the future of brake disc types.

Peak Performance for Extreme Conditions

Carbon ceramic rotors excel in high-heat, high-demand situations:

- Unmatched resistance to brake fade

- Excellent pedal consistency regardless of temperature

- Significant reduction in unsprung weight enhances vehicle responsiveness

- Maintains structural integrity under extreme stress

- Provides reliable stopping power lap after lap

Where You’ll Find These Brake Disc Types

Due to their cost and performance profile, carbon ceramic brake disc types are generally reserved for:

- Supercars and hypercars

- High-end performance sedans

- Limited-production models

- Track-focused sports cars

- Vehicles designed with cost-no-object engineering

Price Tag vs. Performance

The extreme performance of carbon ceramic brakes comes at a steep price:

- Typically 5–10x the cost of traditional rotor setups

- Replacement can cost over $10,000 per axle

- Requires specialized servicing and proper bedding-in techniques

- Improper maintenance can lead to expensive failures

That said, they’re not just for show. For track enthusiasts or owners of ultra-high-performance vehicles, carbon ceramic brake disc types may offer long-term value thanks to their longevity and fade resistance. But for most drivers, they remain more of a status symbol than a functional necessity.

8. Specialized Brake Disc Types for Specific Applications

Beyond the mainstream brake disc types, there’s an entire spectrum of specialized designs crafted to meet the demands of unique vehicles and driving conditions. These aren’t your everyday rotors — they’re engineered with laser focus on purpose-driven performance.

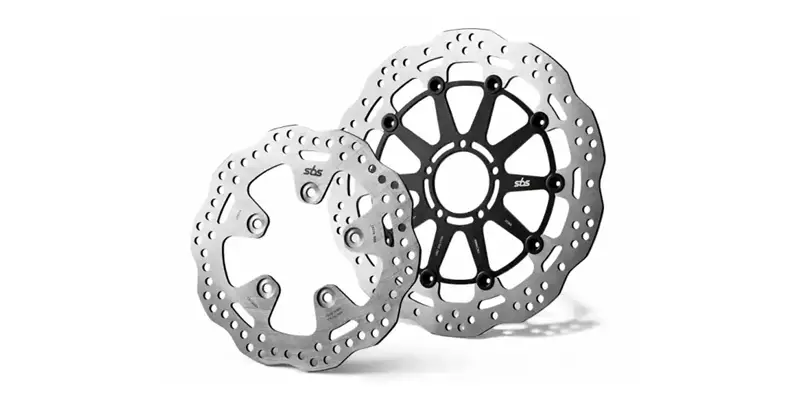

- Motorcycle-specific discs that balance ultra-lightweight construction with rapid heat dissipation

- Truck brake disc types designed to endure extreme weight and constant heat cycling

- EV-compatible discs that work in harmony with regenerative braking systems

- Off-road variants built to resist mud, debris, and corrosion

- Purpose-built racing discs featuring advanced composites and exotic cooling methods

Back when I worked with a motorcycle racing team, I was blown away by the featherlight rotors used on superbikes. Despite their size, they handled brutal track conditions without flinching — a testament to the power of specialization in brake disc types.

Brake Discs for Heavy-Duty and Commercial Use

For commercial vehicles, specialized brake rotor types are mission-critical:

- Extra-thick rotors to absorb and dissipate massive amounts of heat

- Reinforced vane architecture for prolonged braking under heavy loads

- Unique alloy blends that resist warping and cracking

- Some systems incorporate forced-air or even water-cooling for industrial use

- Designed to function reliably during frequent, sustained braking — not just occasional stops

These advanced brake disc solutions may not make headlines, but they’re the unsung heroes of industries where downtime and brake failure simply aren’t an option. They highlight just how diverse and application-specific brake rotor types have become in the modern automotive world.

Motorcycle and EV Brake Disc Innovation: Specialized Engineering for Unique Needs

Not all brake disc types are created with cars in mind. In fact, two of the fastest-growing categories — motorcycles and electric vehicles — are driving some of the most creative advances in braking technology today.

Motorcycle Brake Disc Advances

Two-wheeled performance has always demanded lightweight, high-performance braking systems, and the latest brake disc types for motorcycles reflect that need:

- Wave or petal-style rotors help shed heat and debris while trimming excess material

- Floating disc mounts allow lateral movement to handle extreme heat without warping

- Full-floating systems eliminate the stress points that lead to warping under aggressive braking

- Stainless steel construction improves durability and resists corrosion from the elements

- Ultra-lightweight discs reduce unsprung mass for faster suspension response and better handling

Having worked trackside with a competitive motorcycle team, I can tell you — the difference in performance between a standard rotor and a purpose-built racing disc is night and day. These brake rotor types are engineered to stop hard without dragging down performance.

Electric Vehicle Brake Disc Types

Electric vehicles may rely heavily on regenerative braking, but traditional friction brakes still play a vital role — especially in emergencies or spirited driving. That’s prompted a new class of brake rotor types designed specifically for EV needs:

- Anti-corrosion coatings help combat rust from infrequent use

- Special alloys stand up to the unique heating and cooling cycles caused by regen braking

- Low-mass rotors contribute to extending overall battery range

- Noise-dampening designs help eliminate unwanted sounds in otherwise silent cabins

- Low-maintenance surfaces reduce service intervals for fleets and daily drivers alike

From consulting with EV fleet operators, I’ve learned that picking the right disc isn’t just about stopping power. When chosen correctly, these specialized brake rotor types can reduce long-term costs and improve safety — especially when tailored to a specific application.

Selecting the Right Brake Disc Type for Your Needs

With all these options available, how do you choose the right brake disc type for your specific vehicle and driving style? Let me share some practical guidance based on real-world factors.

- Assess your actual driving conditions honestly

- Consider your performance expectations realistically

- Evaluate your maintenance habits and preferences

- Factor in your budget for both initial purchase and long-term maintenance

- Think about the expected service life in your specific application

One of my most satisfied customers was a gentleman who initially wanted carbon ceramics for his sports sedan, but after discussing his actual driving habits (mostly highway with occasional spirited weekend drives), we settled on slotted discs that provided the performance he needed at a fraction of the cost.

Matching Disc Type to Driving Style

Your typical driving patterns should heavily influence your choice:

- Daily commuting: Standard vented discs offer the best balance of performance and value

- Spirited canyon drives: Slotted discs provide fade resistance without excessive cost

- Occasional track days: Slotted or drilled/slotted combination discs are ideal

- Heavy towing or hauling: Heavy-duty slotted discs manage the sustained heat best

- Off-road vehicles: Coated vented discs resist the corrosion from water exposure

Budget and Installation: The Real-World Side of Brake Disc Selection

While it’s tempting to focus purely on performance specs, real-world considerations like budget and compatibility often have the final say when it comes to choosing between different brake disc types.

Budget Considerations

Let’s be honest — most of us aren’t outfitting a race car. Financial constraints matter, and choosing the right brake disc types starts with setting realistic expectations:

- Figure out your total budget, including installation and any extra labor

- Think about how often you’ll need to replace your discs based on your driving habits

- Don’t forget the cost of related components like brake pads and fluid

- Balance upfront savings with long-term value and performance

- Keep in mind: the cheapest option might cost you more over time in performance, safety, or durability

I’ve seen too many people regret buying budget discs that wore out quickly or didn’t hold up under pressure. A modest upgrade can pay off in better longevity and fewer surprise repairs.

Installation and Compatibility Factors

Once you’ve zeroed in on the best brake disc types for your vehicle, make sure they actually fit — literally and functionally:

- Always double-check the disc dimensions against your make and model

- Ensure the new disc meets the minimum thickness requirements for safe caliper operation

- Make sure your current brake pads are compatible (or be ready to replace them)

- Some high-performance discs require specialized tools or procedures for installation

- Follow the proper break-in or bedding-in process to ensure peak performance from day one

From my experience in the shop, the costliest mistake drivers make isn’t buying cheap — it’s buying the wrong part. Whether you’re upgrading or simply replacing worn components, the best value always comes from matching the right brake disc type to your specific vehicle and driving needs.

Need a mechanic? Find one on the Mobile Mechanic Directory

Conclusion: Making Your Final Decision About Buying the Right Brake Discs

We’ve covered substantial ground in our exploration of brake disc types, examining everything from basic solid discs to exotic carbon ceramic options. Now it’s time to synthesize this information into actionable guidance.

The best brake disc for you isn’t necessarily the most expensive or the one with the most impressive specifications — it’s the one that best matches your specific vehicle, driving style, and budget. Here’s my straightforward advice after years in the field:

- For most daily drivers, quality vented discs offer the best balance of performance, durability, and value.

- If you drive enthusiastically or experience even occasional brake fade, stepping up to slotted discs is a worthwhile investment.

- Drilled discs make sense primarily for their appearance and slight advantage in wet conditions.

- Two-piece and composite discs deliver real benefits for track use and performance applications.

- Carbon ceramic discs remain a specialty option justified only for the most demanding users or exotic vehicles.

Remember that your brake system works as an integrated whole. The finest discs paired with budget pads and degraded fluid won’t deliver optimal performance. Approach your brake system holistically for the best results.