If you’ve ever noticed your steering getting stiff during hot summer drives or after towing a heavy trailer, you might be dealing with overheated power steering fluid. That’s where a power steering cooler comes into play – a simple yet crucial component that can save you from expensive repairs and keep your driving experience comfortable.

Key Takeaways

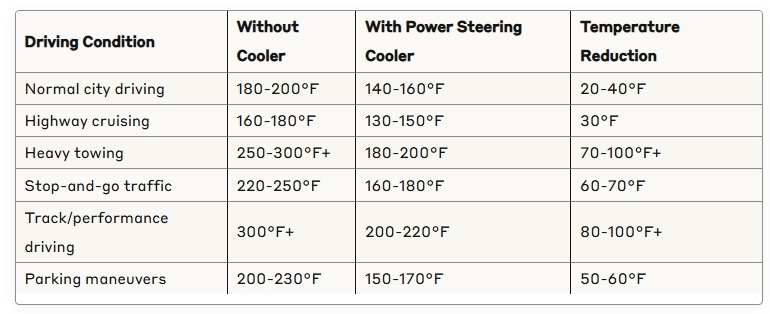

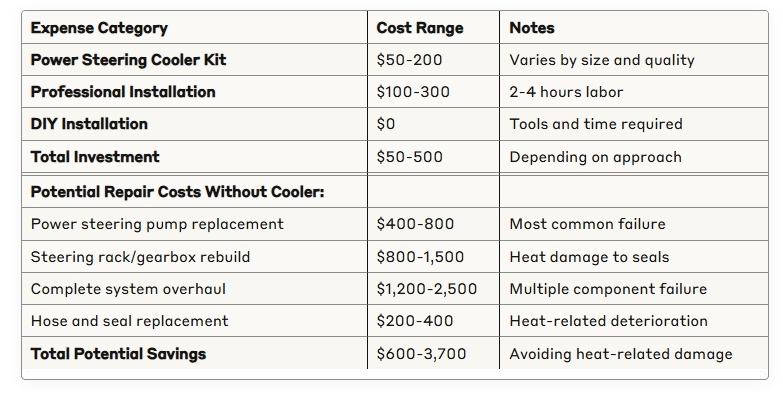

- Quick Overview: A power steering cooler can reduce fluid temperatures by 60-100°F, preventing costly system failures that can cost $800-2,500 to repair.

- Who Needs One: Essential for trucks that tow, performance cars, vehicles in hot climates, and anyone experiencing heavy steering during extended driving.

- Cost vs. Benefit: Invest $50-500 now to avoid potential repair costs of $600-3,700 later, plus enjoy extended maintenance intervals.

- Critical Warning: Avoid these 6 deadly mistakes – wrong sizing, poor mounting location, incorrect hoses, improper connections, skipping system bleeding, and neglecting maintenance.

- Installation Reality: Moderate DIY project (3-5 hours) or 2-hour professional job. Wrong installation can destroy your entire power steering system.

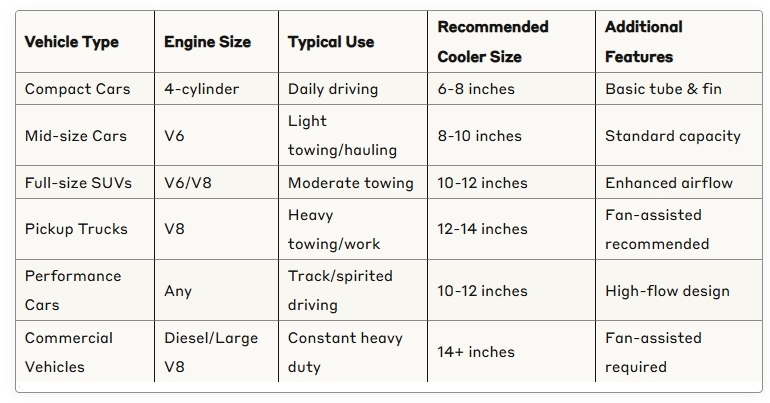

- Sizing Guide: Compact cars need 6-8″ coolers, trucks require 10-14″, and performance vehicles benefit from 12″+ units with fan assistance.

Most drivers don’t think much about their power steering system until something goes wrong. But understanding how a power steering cooler works and when you might need one can help you make informed decisions about your vehicle’s maintenance and performance upgrades.

Table of Contents

What Exactly Is a Power Steering Cooler?

A power steering cooler is essentially a small radiator designed specifically for your power steering fluid. Just like your engine’s cooling system, it helps regulate temperature by allowing hot fluid to flow through cooling fins or tubes where air passes over them, dissipating heat before the fluid returns to your power steering system.

The basic concept is straightforward: hot power steering fluid enters the cooler, gets cooled down by airflow, and returns to the system at a lower temperature. This process helps maintain optimal fluid viscosity and prevents the breakdown of seals and other components that can occur when temperatures get too high.

Most power steering coolers are compact units that mount in front of your vehicle’s radiator or in another location where they can receive adequate airflow. They’re typically made from aluminum or other heat-conducting materials and feature a series of tubes or passages that maximize surface area for heat transfer.

Power Steering Oil Leak: 7 Costly Mistakes Drivers Make (And How to Avoid Them)

Why Your Vehicle Might Need a Power Steering Cooler

Not every vehicle comes with a power steering cooler from the factory, but that doesn’t mean it wouldn’t benefit from one. Several driving conditions and vehicle uses can put extra stress on your power steering system, causing fluid temperatures to rise beyond normal operating ranges.

Heavy-duty applications like towing trailers, hauling heavy loads, or frequent stop-and-go city driving can generate significant heat in your power steering system. When you’re constantly turning the wheel at low speeds or holding it at full lock, your power steering pump works overtime, creating friction and heat.

Performance driving and racing also create conditions where a power steering cooler becomes essential. Track days, autocross events, or spirited canyon drives involve sustained periods of aggressive steering inputs that can quickly overheat standard power steering systems.

Some vehicles are simply more prone to power steering overheating due to their design. Trucks, SUVs, and vehicles with heavy steering systems often benefit from aftermarket power steering coolers, especially if they’re used for work or recreational activities that push the system harder than typical daily driving.

Signs Your Power Steering System Is Running Too Hot

Recognizing the symptoms of an overheated power steering system can help you determine whether you need a power steering cooler. These warning signs often develop gradually, so paying attention to changes in your steering feel is important.

- Stiff or heavy steering, especially when parking or maneuvering at low speeds, is often the first sign of trouble. If your steering feels normal when you first start driving but becomes progressively heavier as you drive, heat buildup could be the culprit.

- Unusual noises from your power steering system can also indicate overheating issues. Whining, groaning, or squealing sounds when turning the wheel often mean your fluid is breaking down or your pump is working harder than it should.

- Visual inspection of your power steering fluid can reveal a lot about your system’s health. Fluid that’s dark, thick, or has a burnt smell has likely been subjected to excessive heat. Fresh power steering fluid should be relatively clear and have a clean, neutral odor.

- Fluid leaks around power steering components might indicate that seals are failing due to heat damage. While leaks can have various causes, chronic overheating accelerates seal deterioration and can lead to costly repairs.

Different Types of Power Steering Coolers Available

When shopping for a power steering cooler, you’ll encounter several different designs, each with its own advantages and ideal applications. Understanding these differences can help you choose the right cooler for your specific needs and budget.

- Tube and fin coolers are the most common type, featuring rows of tubes with aluminum fins attached to increase surface area. These coolers offer good heat dissipation and are relatively affordable, making them popular for most automotive applications. They’re available in various sizes to fit different vehicles and cooling requirements.

- Plate and fin coolers use a different design approach, with alternating layers of plates and fins that create a more compact unit with excellent heat transfer characteristics. These coolers are often more expensive but can be more efficient in tight spaces where mounting room is limited.

- Some power steering coolers include built-in fans for additional cooling capacity. These electric fan-assisted units are ideal for vehicles that don’t receive adequate airflow at low speeds or for extreme-duty applications where maximum cooling is required.

- Remote mount coolers offer flexibility in installation, allowing you to position the cooling unit in an optimal location for airflow while running hoses to connect it to your power steering system. This design works well for vehicles with limited space near the radiator or for custom installations.

How to Choose the Right Power Steering Cooler

Selecting an appropriate power steering cooler involves considering several factors related to your vehicle, driving habits, and performance requirements. Getting the right size and type ensures optimal performance without unnecessary expense or installation complications.

Power Steering Cooler Sizing Chart

Temperature Reduction Comparison

Your vehicle’s power steering system capacity is a crucial starting point. Larger systems with more fluid volume generally require bigger coolers to maintain proper temperatures. Check your owner’s manual or consult with a parts professional to determine your system’s specifications.

Consider your typical driving conditions when sizing a power steering cooler. Daily commuting in moderate climates requires less cooling capacity than regular towing, off-road driving, or track use. Honest assessment of how you use your vehicle helps avoid over- or under-sizing your cooler.

Available mounting space in your vehicle influences cooler selection significantly. Measure the area where you plan to install the cooler and compare it to the dimensions of potential units. Remember to account for hose routing and clearance requirements.

Aluminum Coolers

Quality and construction materials matter for longevity and performance. Aluminum coolers with brazed construction typically offer the best combination of heat transfer, durability, and weight. Avoid coolers with plastic components in high-heat applications.

Installation Process and What to Expect

Installing a power steering cooler is generally straightforward, but it requires some mechanical aptitude and basic tools. Most installations can be completed in a few hours with careful planning and attention to detail.

The typical installation process involves mounting the cooler in a location with good airflow, usually in front of the radiator or air conditioning condenser. Secure mounting is essential to prevent vibration damage and ensure the cooler stays properly positioned.

Connecting The Power Steering Oil Cooler

Connecting the cooler to your power steering system requires identifying the appropriate points in the fluid circuit. Most installations involve cutting the return line from the steering gear to the reservoir and routing it through the cooler before returning to the reservoir.

Proper hose routing is critical for both function and longevity. Hoses should be secured to prevent rubbing against other components and positioned to avoid sharp bends that could restrict flow. Use appropriate clamps and fittings designed for power steering pressures.

After installation, the system needs to be bled properly to remove air bubbles. This process typically involves running the engine and turning the steering wheel through its full range of motion while monitoring fluid levels and watching for leaks.

Maintenance Tips for Your Power Steering Cooler

Like any automotive component, a power steering cooler requires periodic maintenance to ensure optimal performance and longevity. Establishing a regular maintenance routine helps prevent problems and extends the life of your entire power steering system.

Regular visual inspections should include checking for leaks at connection points, examining hoses for signs of wear or damage, and ensuring the cooler fins aren’t clogged with debris. Road dirt, leaves, and insects can reduce cooling efficiency if allowed to accumulate.

Cleaning the cooler periodically helps maintain peak performance. Use compressed air to blow debris from between the fins, working from the back side toward the front to push contaminants out rather than deeper into the cooler. For stubborn buildup, gentle washing with water and mild detergent can help.

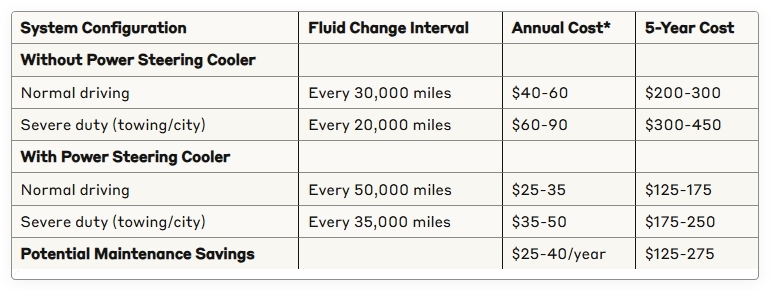

Power steering fluid should be changed according to your vehicle manufacturer’s recommendations, which often becomes more important with a cooler installed. Fresh fluid transfers heat more effectively and helps prevent corrosion within the cooling system.

After Installing A New Cooler

Monitor your power steering fluid level and condition regularly, especially after installing a new cooler. The additional volume in the cooling circuit may require slightly more fluid, and any changes in fluid appearance or smell could indicate developing problems.

6 Costly Power Steering Cooler Mistakes That Destroy Your System

Avoiding these critical mistakes can save you thousands in repairs and prevent catastrophic system failure. These errors are surprisingly common and can turn a beneficial upgrade into an expensive disaster.

- Installing the Wrong Size Cooler is one of the most frequent and costly mistakes. Many people choose coolers that are either too small for their system’s capacity or oversized for their application. An undersized power steering cooler won’t provide adequate cooling, leading to continued overheating and component failure. An oversized cooler can cause fluid to cool too rapidly, affecting viscosity and pump performance.

- Poor Mounting Location with Inadequate Airflow renders your cooler nearly useless. Common mistakes include mounting behind the radiator where hot air hits it first, or in enclosed areas with no ventilation. This leads to minimal cooling benefit and wasted investment in your power steering cooler.

- Using Incorrect Hoses and Fittings is a recipe for disaster. Installing a cooler with standard automotive hoses instead of power steering-rated hoses can be catastrophic. Power steering systems operate at much higher pressures than cooling systems, and wrong hoses can burst, causing complete fluid loss and pump destruction within minutes.

- Improper Connection Points in the System can create restrictions, reverse flow, or bypass the cooler entirely. The most common mistake is tapping into the pressure side instead of the return line, which can damage your power steering cooler and create dangerous pressure situations.

- Skipping Proper System Bleeding After Installation leaves air pockets that cause pump cavitation, erratic steering, and premature pump failure. Many DIYers rush this step, not realizing that air in the system can destroy a power steering pump in hours.

- Neglecting Regular Cooler Maintenance leads to clogged fins, internal corrosion, and eventual system failure. Installing a power steering cooler and forgetting about it allows debris buildup that reduces cooling efficiency, while old fluid becomes acidic and eats away at seals and internal components.

Benefits Beyond Just Cooling

While temperature control is the primary function of a power steering cooler, installing one can provide several additional benefits that improve your overall driving experience and vehicle reliability.

Cost Analysis: Investment vs. Potential Repairs

Maintenance Interval Comparison

*Based on average annual mileage of 12,000-15,000 miles

Installation Difficulty & Time Guide

Extended component life throughout your power steering system results from maintaining proper operating temperatures. Seals, hoses, and the power steering pump itself last longer when not subjected to excessive heat cycling and thermal stress.

Improved steering feel and consistency, especially during demanding driving conditions, make your vehicle more predictable and enjoyable to drive. Consistent fluid viscosity means consistent steering effort and response regardless of operating conditions.

Reduced Maintenance Requirements

Reduced maintenance requirements often follow power steering cooler installation. Cooler-running systems typically need less frequent fluid changes and experience fewer seal failures, reducing long-term ownership costs.

Enhanced towing and hauling capabilities become possible when your power steering system can handle sustained heavy-duty use without overheating. This improvement is particularly valuable for work trucks and recreational vehicles.

Frequently Asked Questions

-

Do all vehicles need a power steering cooler?

Not all vehicles require a power steering cooler. Most cars used for normal daily driving operate fine with their factory cooling systems. However, vehicles used for towing, heavy-duty work, performance driving, or those experiencing steering problems in hot weather can benefit significantly from adding a power steering cooler.

-

How much does it cost to install a power steering cooler?

A basic power steering cooler kit typically costs between $50-200, depending on size and quality. Professional installation usually adds $100-300 in labor costs. DIY installation is possible for mechanically inclined individuals and can save on labor expenses

-

Can I install a power steering cooler myself?

Yes, installing a power steering cooler is within the capabilities of most DIY mechanics. The process requires basic tools, some mechanical knowledge, and careful attention to proper hose routing and connections. Always follow manufacturer instructions and ensure proper system bleeding after installation.

-

How often should I clean my power steering cooler?

Inspect and clean your power steering cooler every 6-12 months or more frequently if you drive in dusty conditions. Remove debris from the fins with compressed air and check for any signs of damage or leaks during regular maintenance intervals.

-

Will a power steering cooler affect my vehicle’s warranty?

Adding aftermarket components like a power steering cooler shouldn’t void your entire vehicle warranty, but manufacturers might not cover problems directly related to the modification. Check with your dealer and consider professional installation to minimize any warranty concerns.

-

What size power steering cooler do I need?

Cooler sizing depends on your vehicle’s power steering system capacity and intended use. Most passenger cars work well with smaller coolers (6-8 inches), while trucks and heavy-duty applications may need larger units (10-12 inches or more). Consult with parts professionals for specific recommendations.

-

Can a power steering cooler leak?

Like any fluid-carrying component, power steering coolers can develop leaks over time. Most leaks occur at connection points and can be fixed by tightening fittings or replacing hoses. Internal cooler leaks are less common but may require cooler replacement.

Need a mechanic? Find one on the Mobile Mechanic Directory

Final Thoughts

A power steering cooler might seem like a small addition to your vehicle, but it can make a significant difference in performance, reliability, and component longevity. Whether you’re dealing with current overheating issues or looking to prevent future problems, understanding how these systems work helps you make informed decisions about your vehicle’s maintenance and upgrades.

The investment in a quality power steering cooler often pays for itself through reduced maintenance costs and improved driving experience. For vehicles used in demanding conditions or by drivers who want the best possible steering performance, a power steering cooler represents a smart upgrade that addresses a common weak point in many automotive systems.

Remember that proper installation and maintenance are key to getting the most benefit from your power steering cooler. Take time to choose the right unit for your application, install it correctly, and maintain it regularly to ensure years of reliable service and improved steering performance.